HPT-100 FI - Vacuum Plasma treatment system

The Henniker Plasma HPT100 low pressure plasma treatment systems are microprocessor controlled bench-top devices that are ideal for routine laboratory, R&D and light industrial tasks.

HPT 100 FI

Henniker Plasma’s HPT plasma systems are perfect for surface cleaning, surface preparation and surface modification of a wide range of materials including metals, glass, polymers, ceramics, plastics and composites. Key applications include composites joining development, microfluidics PDMS bonding, microscope sample cleaning, optics cleaning, metals cleaning, biomedical applications, polymer science and medical device manufacture.

Due to their ease of use and reliability, they are the instrument of choice for many of the world’s leading companies and institutes, where they are used to activate materials in order to increase wettability and improve adhesion.

These devices feature a fixed flow of process gas, without the option for adjustment. While they may lack the variety of options or enhancement features available in our models, they are excellent for occasional use and offer a great value proposition, meeting your needs.

HPT 100 Fixed Air version main specifications:

- The airflow is set, so there is no extra option for adding additional gas into the process. It is the basic version of the device.

- BenchTop housing with dimensions: W: 520 x H: 286 x D: 550 mm

- Weight 22kg,

- Cylindrical chamber Ø 100 x 280 mm,

- Aluminum insert (base) sized 90 x 255 mm

- Power 0...100W smoothly adjustable by a 40 kHz power supply,

- User interface: 5.7" TFT touchscreen panel,

- Programmable timer 0... 99min with 1s resolution,

- Vacuum process measurement and control,

- Power supply 230 VAC

- The device needs an oil or dry pump for proper operation

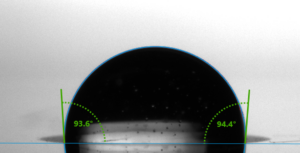

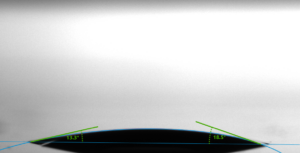

Plasma Cleaning Example

- Material : HDPE

- Air plasma

- 90 seconds

Your Dynamic Snippet will be displayed here...

This message is displayed because youy did not provide both a filter and a template to use.