Description

The Henniker Plasma HPT200 low pressure plasma treatment systems are microprocessor controlled bench-top devices that are ideal for routine laboratory, R&D and light industrial tasks. Due to their ease of use and reliability, they are the instrument of choice for many of the world’s leading companies and institutes, where they are used to activate materials in order to increase wettability and improve adhesion.

HPT200 includes an integrated pressure gauge and precision gas flow controller as well as a suitable vacuum pump, everything needed for operation. Simple recipes are stored via the intuitive touch screen control and are executed with a single button press and, because we do not use analogue timers or unreliable needle valves, process repeatability is guaranteed each and every time.

Henniker Plasma’s HPT plasma systems are perfect for surface cleaning, surface preparation and surface modification of a wide range of materials including metals, glass, polymers, ceramics, plastics and composites.

Key applications include composites joining development, microfluidics PDMS bonding, microscope sample cleaning, optics cleaning, metals cleaning, biomedical applications, polymer science and medical device manufacture.

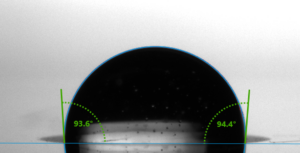

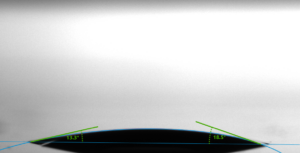

Plasma Cleaning Example

Technical Specifications |

||||||

| HPT-200 Plasma Treatment Systems | ||||||

| ENCLOSURE | ||||||

| Dimensions | HPT-200 – W 520mm x H 286mm x L 550mm (+50mm on rear for cables) | |||||

| Weight |

HPT-200 – ~23kg |

|||||

CHAMBER |

||||||

| Material | Stainless Steel | |||||

| Form | Cylindrical | |||||

| Dimensions |

HPT-200 – 150mm dia. x 280mm L |

|||||

REMOVABLE PARTS CARRIER |

||||||

| Material | Aluminium | |||||

| Material options | Stainless steel | |||||

| Form | Flat tray | |||||

| Form options | Perforated tray, others to suit application | |||||

| Dimensions |

HPT-200 – 135mm W x 255mm L, others to suit application |

|||||

PLASMA POWER SUPPLY |

||||||

| Power |

HPT-200 – 0-200W, continuously variable output |

|||||

| Frequency | 40 kHz | |||||

PROCESS CONTROL |

||||||

| Interface | 5.7” Colour TFT with recipe store | |||||

| Gas channel options | Fixed, x1 MFC or x2 MFC and x1 vapour inlet options | |||||

| Vent inlet | x1 | |||||

| Vent inlet options | soft ventilation option | |||||

| Connections | 6mm compression or 1/4″ compression | |||||

| Process timer | 1sec – 99.59min | |||||

| Recipe Store |

Stores up to 4 x recipes – with individual parameters | |||||

| Pressure gauge | Pirani sensor | |||||

| Vacuum pump | 3 to 6 m3/hr pumping speed | |||||

| Vacuum pump options | 2-stage rotary pump (air/inert gas), PFPE rotary pump (oxygen compatible), dry pumps. All pumps include exhaust filter and connections | |||||

SERVICES |

||||||

| Electrical | 90-250 VAC, 50-60Hz, 1200-1500 VA (including pump), fused 6.3 A T / 10 A T | |||||

| Power cord | Suited to region | |||||

| Compliance | CE – UKCA – ROHS – WEEE | |||||

| **Henniker strive for continuous improvement and specifications are subject to change without notice | ||||||